PRODUCTS

Valves

We are proud to stock Canada’s largest selection of valves from among the worlds best manufacturers.

Ball Valves

Plug Valves

Expanding Gate Valves

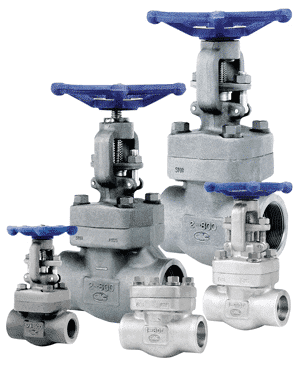

Forged Steel Valves

Diverter Valves

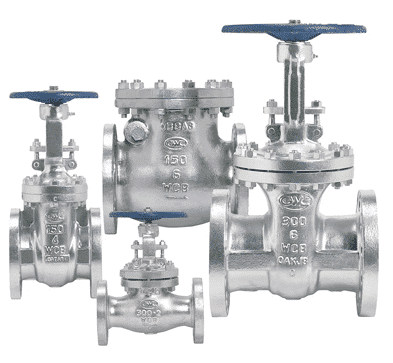

Cast Steel Valves

Don’t see what you’re looking for? Need help?

Ask us and we’ll be happy to find a solution for your needs.